HomeBackDesign & Specification

Fire door specifications & designs

Get inspired and bring your vision to life with timber solutions that are both beautiful and compliant

Quality product

Exceptional timber doors & joinery crafted with precision.

Sustainably made

Support your sustainability goals with locally-made FSC-certified products.

Assured safety

Industry-leading certification & knowledge you can count on.

On time, every time

Reliable on time delivery keeping your projects perfectly on track.

Discover what's possible with fire-rated timber doors & joinery for your next project

Get inspired and bring your vision to life with timber solutions that are both beautiful and compliant.

Useful Resources

We know your time is precious, jump straight to the resources you need.

InspirationExplore our showcase of innovative spaces to spark your next design.

InspirationExplore our showcase of innovative spaces to spark your next design. ProductsBrowse our bespoke high-performance timber solutions.

ProductsBrowse our bespoke high-performance timber solutions. DownloadsAccess comprehensive technical resources to support your specification.

DownloadsAccess comprehensive technical resources to support your specification. SustainabilityChoose environmentally responsible materials for tomorrow's built environment.

SustainabilityChoose environmentally responsible materials for tomorrow's built environment.Elevating spaces with exceptional craftsmanship for over 15 years

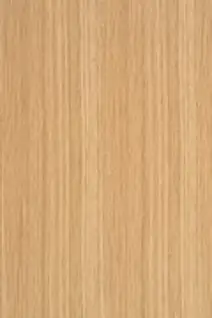

Working with veneer requires a keen eye, steady hands and precision tools. With decades of experience, our team brings exceptional skill and dedication to their work, guaranteeing a flawless finish every time.

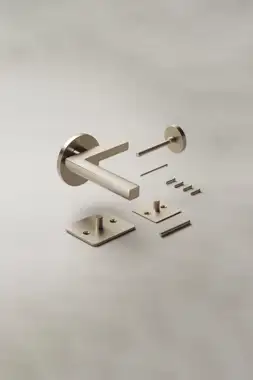

Veneers & Finishes

Browse our diverse range of veneers and finishes, designed to suit every taste and enhance any space.

Niveus

Eucalyptus

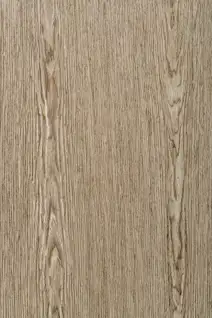

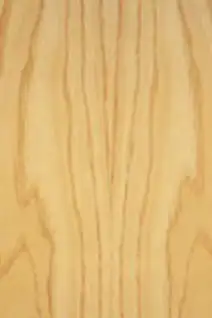

Crown Cut Oak

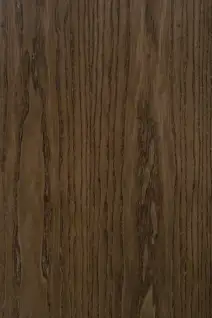

Oak

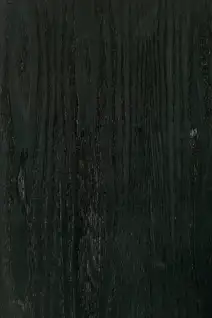

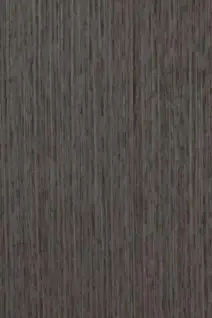

Piceus

Ash

Solid Cashmere Grey

U7021 ST9

Litus

Mulitilaminar (Oak)

Imber

Mulitilaminar (Oak)

Graphite Grey

U961 ST7

Terra

Ash

Vesperi

Multilaminar (Poplar)

Aged Ash

F8844

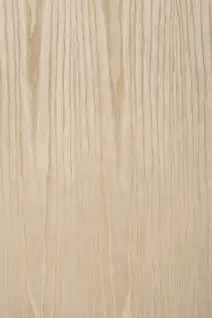

Albus

Ash

Misty Blue

U502 ST9

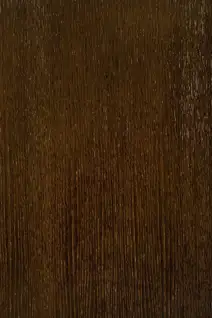

Furvus

Ash

Alpino

F1040

Terracotta

F4161

Crown Cut Ash

Ash

Artichoke

F0800

Quarter Cut White Oak

OakOur Certification & Partners

We partner with the industry's most respected organisations, ensuring we maintain rigorous safety standards whilst delivering uncompromising quality and craftsmanship.

Trusted by construction leaders

Ready to get started?

Get in touch to request a quote or discuss a project.